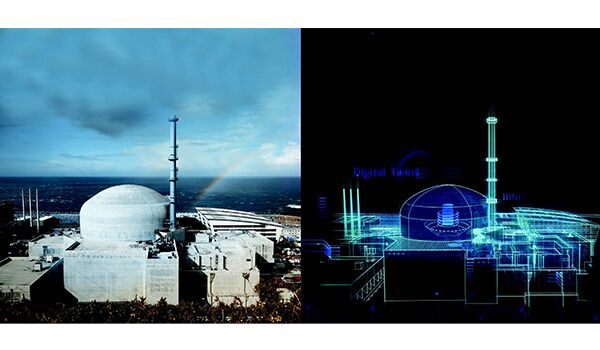

Réacteur numérique (‘Digital Reactor’) is an R&D project undertaken by nine French companies working in the nuclear industry. The four-year project seeks to develop a digital twin of a power plant that can be used from design right through to deconstruction. CORYS is one of the companies involved, and responsible for the functional integration bench.

Digital twins have been all the rage recently in the trade press and professional exhibitions, and the Réacteur numérique project funded by French public investment bank Bpifrance marks a major step forward with the practical implementation of a digital reactor. The project is being headed up by three key nuclear stakeholders: EDF, French Atomic Energy Commission CEA, and Framatome. Working with them are six other firms, including CORYS, with recognised expertise in simulation, advanced visualisation, real-time modelling, and related fields.

Didier Paen, CORYS Business Developer, project manager for one of the Réacteur numérique workpackages says:

“The idea is to engage in collaborative R&D. We’ll be sharing data, ensuring code is interoperable, and pooling our findings, in line with the ‘extended enterprise’ concept implemented in the aerospace and automotive industries.”

Indeed, EDF is making its LEGO power plant case study, which uses data representative of a French reactor, available for this Digital Reactor project.

Using a model of the units where staff work for training purposes

Among the expected project outcomes by 2023 are two innovative products. One is a digital reactor devoted to operator training. This will depict the physical phenomena entailed by operation of the unit, and simulate various operating strategies.

“Instead of a fullscope simulator, operators will use a web interface,” explains Didier Paen. “Rather than describing each system in detail, the model will depict the workings of the installation as a whole. It will also be a faithful reproduction of a specific unit in the French fleet: indeed, achieving this is one of the key challenges.”

The second innovation is an advanced simulation service platform for study purposes. This too will mirror a specific unit, and will be based on coupling qualified multi-physics and multi-scale codes covering an entire life cycle: design, commissioning, operation, maintenance, and even deconstruction. The platform will facilitate a range of studies spanning everything from normal operations to severe accidents.

Benefiting from precedents: the SIRENE 900 MW and 1300 MW simulators

One of the reasons CORYS has been chosen to participate is its experience with engineering simulators, starting with the FA3 project for the EPR Flamanville reactor currently under construction, followed by the SIRENE 900 and 1300 MW projects developed for reactors in the EDF fleet. These simulators also have to replicate specific units, and are used to assess the impact of changes and fuel reloading. CORYS has thus been entrusted with the functional integration bench for the new project.

What technical obstacles need to be overcome? The main challenges include ensuring models supplied by the different partners are interoperable, verifying that unit data supplied is complete and coherent, and compressing models so they can operate in real time despite not being initially designed to do so. The system as a whole will of course use Alices©.

The project has major potential. It will enable studies to become more productive and agile; design conservatism can be identified; costs can be brought down. Operating companies will be able to ensure safe, high-performance operation at all times, and suffer fewer automatic shutdowns. And indeed, the entire nuclear industry will benefit from a brand new digital reactor offering: Réacteur numérique will be marketed in France and internationally.

“The aim is to make our expertise available to the industry as a whole,” concludes Didier Paen.