TECHNOLOGY

Most Advanced Technology

CORYS’ products are widely regarded as state of the art in the nuclear simulation industry.

CORYS technology is state-of-the-art allowing real time dynamic simulation. This same technology is used for engineering tools and full scope simulators optimising investments for our customers.

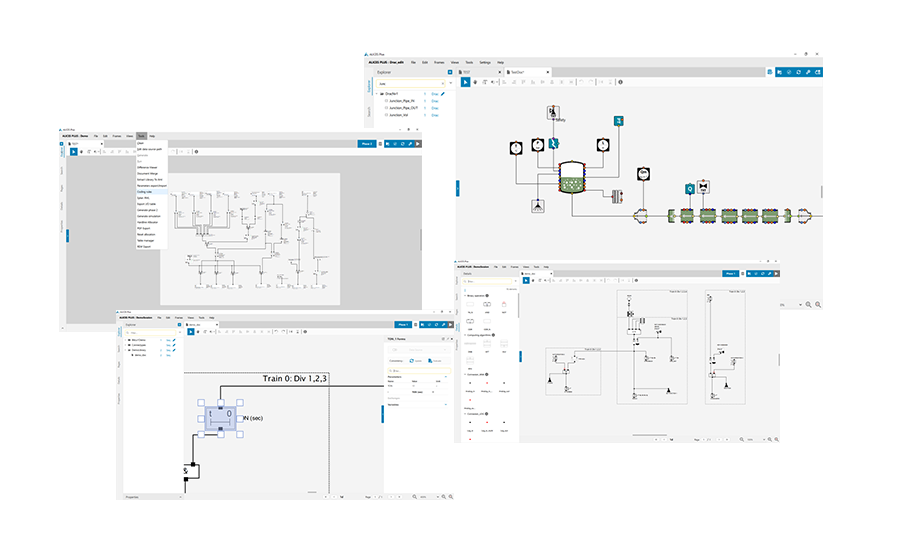

ALICES PLUS®

Integrated simulation toolset

ALICES Plus® delivers CORYS’ decades of expertise providing nuclear industry with advanced engineering and training simulators. At a time when decarbonizing the economy is more pressing than ever, ALICES Plus® is helping the nuclear industry respond to its operating efficiency, safety, performance, and sustainability challenges.

-

ALICES Plus® strengths

ALICES Plus® is characterised by several innovative features which improve productivity at each stage of simulator development:

-

Easier development through modern designed ergonomics

-

Fast and efficient plant model development and update

-

Interoperability and compatibility with multi-OS supports

-

Standardized tools to interface with third-party code and software

-

Automatic interfacing between the different simulator modules

-

No programming skills required

-

State-of-the-art Instructor Station

-

Fully graphical simulator executive

-

Data tracking and consistency management

DRAC Plus

Advanced thermal-hydraulic model

DRAC Plus code is intended for the modelling of two phase thermo-hydraulic flows. Originally designed for the modelling of primary loops with water and sodium in nuclear power plants, its capabilities have been extended:

- To model all hydraulic systems of a nuclear power plant

- To process various fluids like lead and other liquid metals and refrigerating gases

In addition DRAC Plus has the capability to use any suitable fluid table and custom fluid dependent correlations. This makes it is easy to add new fluid support.

DRAC Plus interfaces seamlessly with ALICES Plus®

DRAC Plus is the DRAC version of ALICES Plus®, offering the same physics with extended capabilities. Its ergonomic has been improved to offer a modern and intuitive experience.

DRAC Plus is deployed in several engineering simulators, including for engineering studies with innovative Small Modular Reactor (SMR) concepts, enabling the analysis from normal operation to accidental transient.

DRAC has been successfully implemented and used in numerous training simulators developed by CORYS. It is validated against best estimate safety analysis codes including RELAP 5 and CATHARE. DRAC was also chosen as the reference thermal hydraulic code in the severe accident code ASTEC, jointly developed by IRSN (France) and GRS (Germany).

The use of DRAC for containment model has also been validated against reference calculations based on PAREO (point model containment code for P&T calculations developed and qualified by EDF.

T-REX

Real-time executive and Instructor Station

CORYS T-REX simulator executive, instructor station and toolkit enable a modern feature-rich simulation environment. Our T-Rex simulation platform is the most widely used in the US nuclear industry.

T-REX provides capabilities and ease of use never before seen in the simulator industry and consists of a real-time simulator executive and toolkit, a complete, full-featured instructor station and a sophisticated graphical development environment.

The T-REX instructor station offers a complete set of instructor station applications which are designed for ease of use. Earlier instructor stations required a significant level of expertise to run the simulator during training scenarios and to develop lesson plans. Instructors were required to memorize or look up and type in cryptic database labels or expert commands. The T-REX instructor station uses modern Windows capabilities like drag-and-drop to make this unnecessary.

Instructors are able to operate the simulator with minimal simulator-specific knowledge.

CORYS provides ongoing support and updates for ensuring a long term life cycle to the T-Rex product.

-

T-REX strengths

1st Worldwide

Real-time

User Friendly

Compliant ANSI/ANS-3.5

THOR

Advanced two-phase flow modelling

Since being introduced in 1996, the THOR advanced thermal hydraulic and neutronics models have been installed on more simulators than all other advanced models combined.

-

THOR strengths

1st Worldwide

Any Fluid System

by Nuclear Industry

As a result, THOR models are the most thoroughly tested and benchmarked models in the industry. THOR has modeled reactor coolant systems, reactor cores, and steam supply systems for numerous PWR’s and BWR’s.

In 2001 the first THOR-BOP models were installed on the Dominion Surry nuclear plant simulator, for the first time extending the high fidelity of a true two-phase, five-equation, non-equilibrium numerical solution throughout the secondary plant system models. Since then, numerous simulators have contracted to install THOR-BOP.

As computer processing power continued to increase, it has become possible to extend the THOR models into other areas, including the containment, HVAC and radiation transport model. THOR is used to model any fluid system, be it liquid, gas or two-phase

Interface seamlessly with full scope simulator

The CORYS CAN I/O system provides the ultimate in flexibility. 16 bit precision ensures accuracy.

I/O systems

Setup and replacement is a simple plug-in with external micro switches to set the CAN network address and transmission rate.

The CORYS I/O system modules are based upon standard hardware components and are fully compliant with ISO-11898 for High Speed CAN. Status lights are provided to signal defective wiring and network communication problems.

-

Easy to use utilities for CAN I/O system configuration, monitoring and diagnostics are supplied.

CORYS CAN I/O system is characterized by high throughput, rapid scanning rates and good reliability. Standards-based design and a very large number of installations on nuclear plant and train simulators ensure long term maintenance and support.