CORYS’ ETCS simulator offers operators, infrastructure managers, and certification bodies the perfect way to anticipate this major change. A dozen or so of our clients, spread across seven countries, are already using it.

The key feature of this simulator is that it complies with EU SRS standards for Baselines 2 and 3, allowing users to work in an environment that’s realistic in terms of both rolling stock and infrastructure, even without in-field data: this can be added as the project progresses.

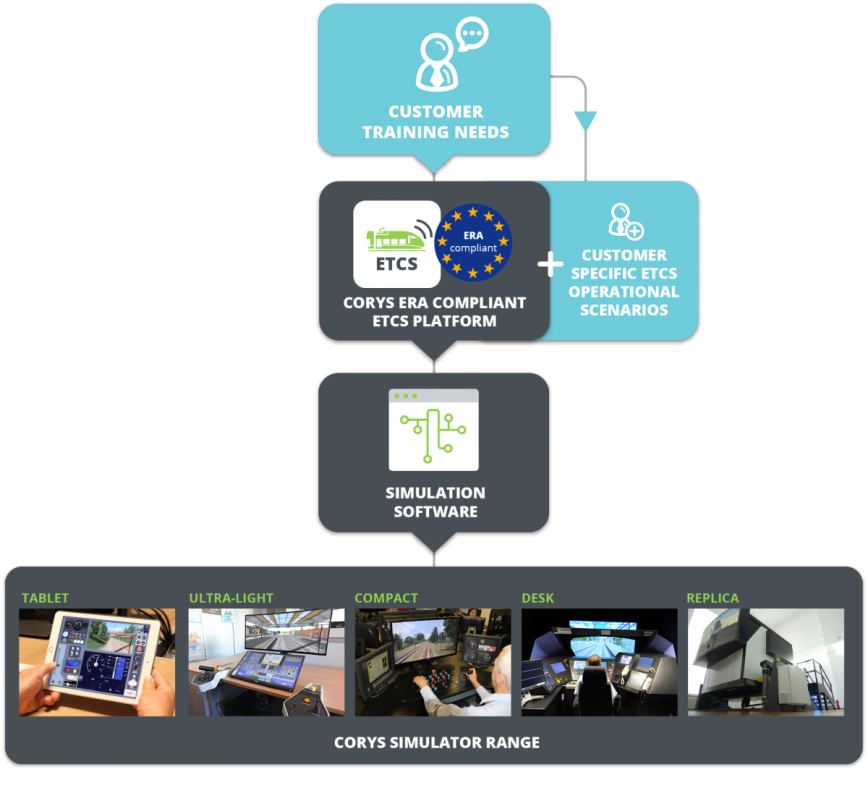

The solution is also modular: the driver machine interface (DMI), on-board computer (EVC), radio block centre (RBC), and all the sub-assemblies can be simulated separately, and be adapted to specific country characteristics and/or rolling stock. Similarly, clients can choose to have the simulator supplied with generic or specific lines. Amongst other things, the specific line option can be used for engineering applications, such as optimising beacon location along the tracks.

Realistic – and flexible enough to simulate everything

CORYS has chosen to simulate ETCS hardware rather than replicate it.

As CORYS account manager Thomas Denis explains, an exact replica would have been counter-productive.

“A digital copy of equipment cannot run scenarios based on specific starting conditions, stop them half-way through, replay them, or allow external values or faults to be configured. Clients need these functions to optimise the system they’ll be using and train their drivers.”

At the same time, the simulation is realistic enough to be used for sophisticated studies. In the UK, for example, LNER (see interview) is using it to determine braking values and understand drivability to prepare new passenger train timetables.

CORYS has installed the simulator on a range of different platforms (see illustration) to make it accessible to existing clients and new partners alike. It has already been installed in seven countries, most of them in Europe, and been certified by several national bodies.