Over the next 12 months, CORYS will be delivering three training simulators for operators, technicians and engineers in gigafactories built to supply electric vehicle batteries. The aim is to address the huge labour requirements in this fast-growing sector which will be hiring 40,000 people a year between now and 2030 in France alone.

Worth €20 million, including €14 million from the French state, and with 12 private and public-sector partners, a ‘Battery school’ will ultimately be training 1,600 professionals per year. CORYS has joined this ambitious scheme, developing three simulators dedicated to entirely new fields.

The delicate business of electrode deposition

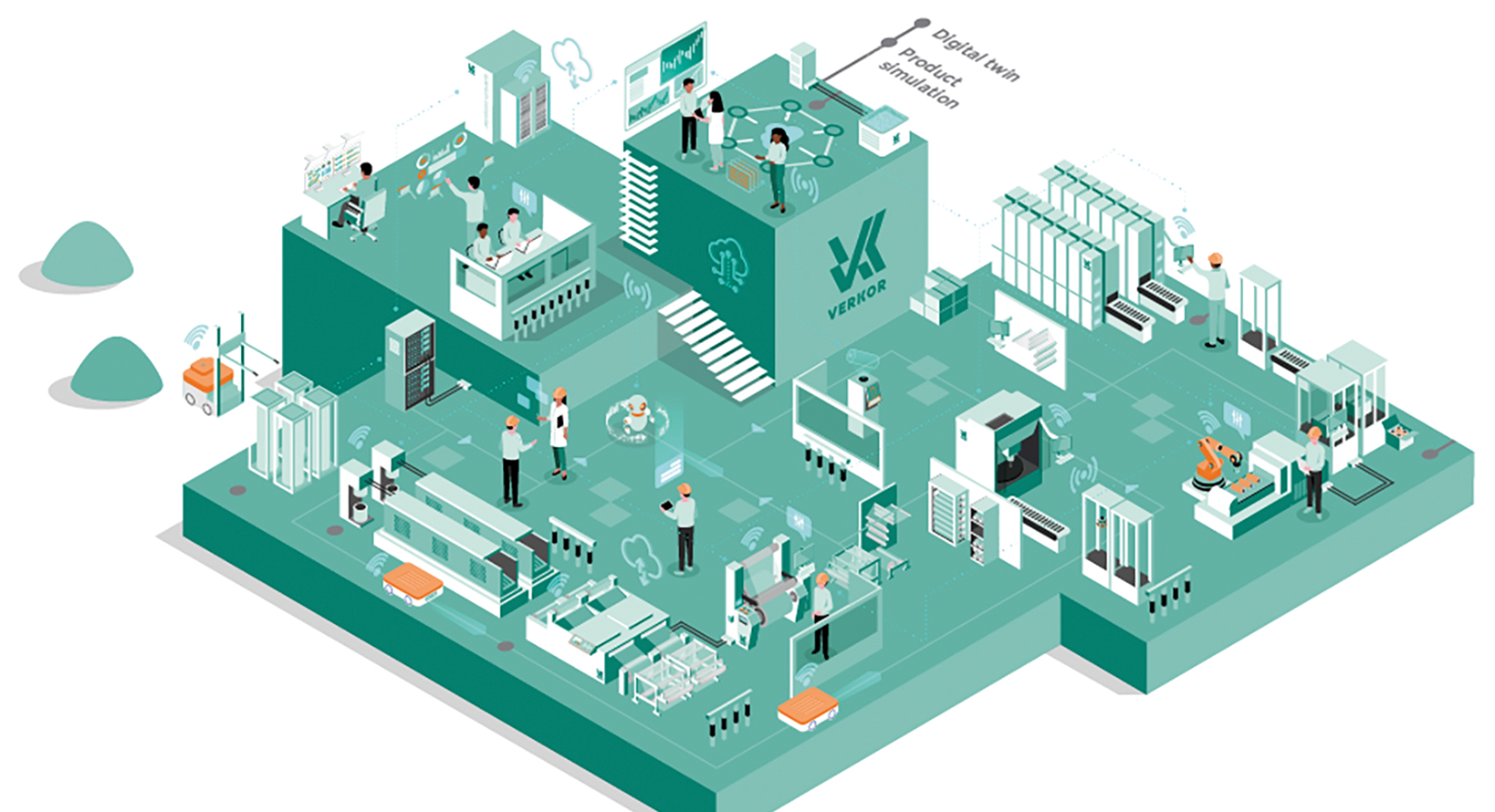

The first simulator will be a generic model of a battery cell manufacturing facility, while the second will be a generic model of a battery recycling factory. The third simulator will cover one of the most delicate stages in the process, the application of electrode coatings, using a 3D model.

As CORYS project manager Jérémy Lemaire explains, “This is done in a dry room, with materials being printed onto aluminium or copper plates. The printing speed, the thickness of the deposit, its temperature, and how it dries are all crucial in terms of battery performance.” All the processes are automated; the future simulator will reproduce supervision screens.

Chemistry, mechanics, and power electronics

To acquire the business knowledge required to model this type of activity, a CORYS team has been mining bibliographical and online resources for several months now.

“We’ve already acquired expertise in a large number of other industrial sectors”, says Jérémy Lemaire. “Examples include modelling a cardboard corrugator machine and the production of synthetic elastomers.”

Battery manufacturing and recycling involve chemistry, mechanics, power electronics and the deposition techniques explained above. These aspects are applied to two battery cell formats: ‘pouch’ cells, offering very high energy density, and rigid, rectangular ‘prismatic’ cells that are easy to stack and thus save space.

“We’re all the more motivated by the Battery School project in that in Europe alone, plans for 40 gigafactories have been announced”, notes Philippe Thiabaud, CORYS Head of Sales, Process Industries. “To the best of our knowledge, no player in dynamic simulation is as yet providing real-time simulation tools for batteries”.

Two classrooms and a distance learning portal

The CORYS systems will be delivered in three stages: 2023 for the generic production facility simulator, early 2024 for the electrode coating application, and mid-2024 for the recycling facility, since no decision has yet been made about the recycling technology to be used in these future factories.

The definitive version of the Battery School will have two bricks-and-mortar classrooms for in-person training, each equipped with 5 PC simulators and an instructor viewer console, as well as a web portal for distance training. Operators, technicians and engineers will be able to acquire basic knowledge and train on specific scenarios.

Meanwhile CORYS has also been selected for a second French battery production training project, Électro’Mob, with funding worth €29 million.

“We’re very much engaged in diversifying our business towards energy transition and low-carbon mobility”, concludes Philippe Thiabaud.